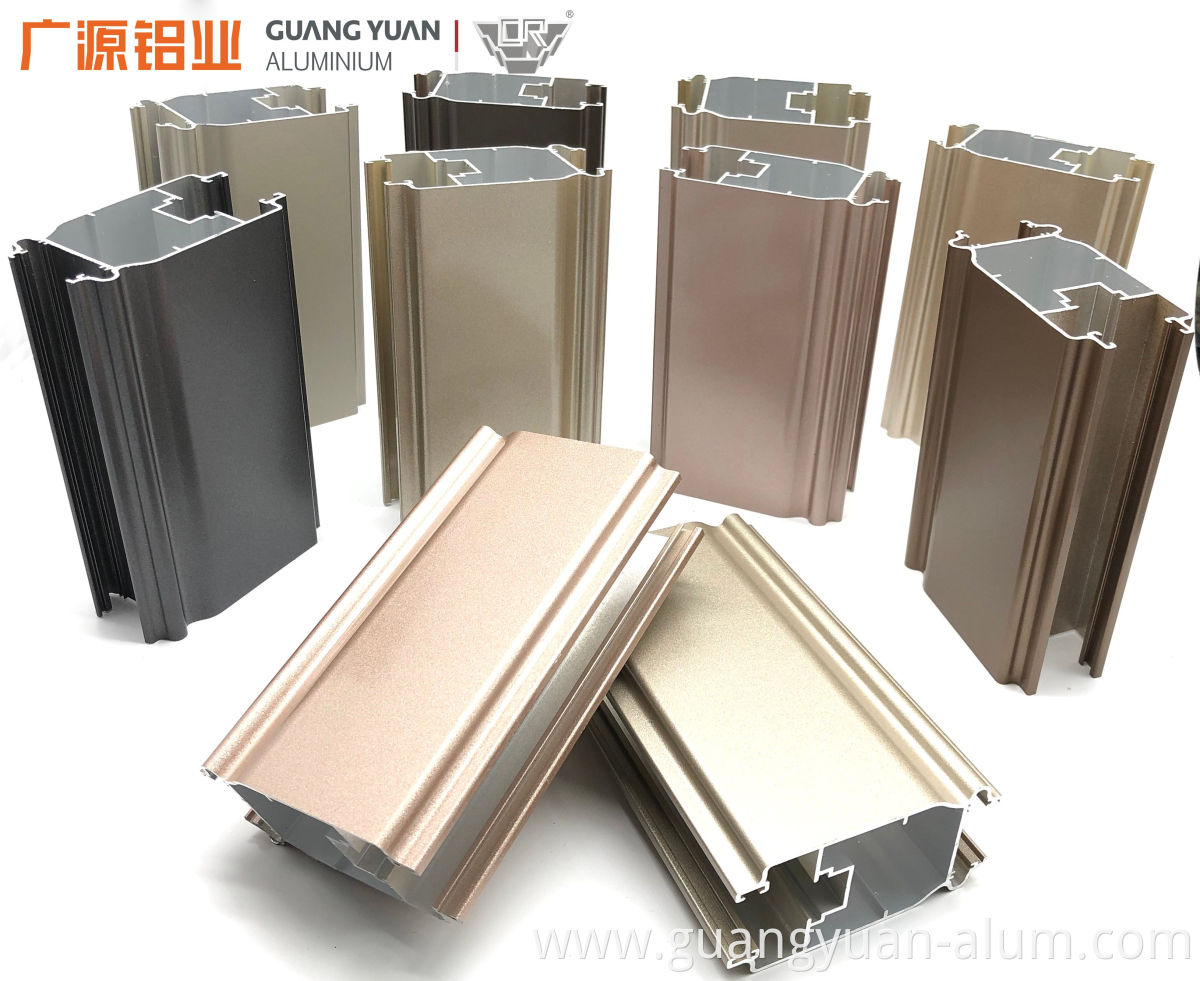

PVDF Aluminium Extrusion Profiles

$2900-3200 /Ton

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,CFR,EXW,DDP,DDU |

| Min. Order: | 1 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Guangzhou,Shenzhen ,Foshan |

$2900-3200 /Ton

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,CFR,EXW,DDP,DDU |

| Min. Order: | 1 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Guangzhou,Shenzhen ,Foshan |

Model No.: GY1007

Brand: GUANGYUAN

Place Of Origin: China

Material: 6000 Series

Annealing: T3-T8

Application: Decorations, Door &Amp; Window, Glass Wall

Shape: Angle, Square, T - Profile

Whether Alloy: Is Alloy

Tolerance: ±1%

Processing Service: Bending, Decoiling, Welding, Punching, Cutting

| Selling Units | : | Ton |

| Package Type | : | Inside: plastic film + Outside: Shrink film; or customized. |

PVDF aluminium extrusion profiles process is:

Pre-treatment process: degreasing and decontamination of aluminum material → washing → alkaline washing (degreasing) → washing → pickling → washing → chromizing → washing → pure water washing

Spraying process: spray primer → top coat → finish varnish → baking (180-250℃) → quality inspection

The generation of electrostatic spraying solves the surface treatment of the curtain wall aluminum plate, which not only reduces the color difference, but also obtains aluminum plates of various colors.

Electrostatic spraying is divided into powder spraying and fluorocarbon spraying. The raw materials of powder spraying are: polyurethane, polyurethane resin, epoxy resin, hydroxy polyester resin and epoxy/polyester resin, which can be formulated in a variety of colors. The characteristics of powder spraying: spraying equipment is manual, with automatic hanging type, simple construction, coating thickness of 30 microns or more, impact resistance, abrasion resistance, corrosion resistance, weather resistance, etc., the coating price is higher than fluorocarbon Cheap. The major weakness of powder spraying is that it is afraid of ultraviolet rays from the sun. Long-term exposure will cause natural fading. The color difference between the sunny side and the non-sunlight side of the aluminum plate will be obvious after a few years, generally 2-5 years. Nowadays, colored PVDF aluminium profiles appear on the market. They are used for aluminum doors and windows and are sprayed with ordinary PVDF aluminIum profile powder. Increase the color variety of aluminum doors and windows, and also enhance the corrosion resistance.

The performance of PVDF aluminium profiles is determined by its performance. The spraying equipment must ensure an excellent atomization effect and the uniformity of the sprayed layer. The distribution of metal particles in the fluorocarbon paint directly affects the appearance of the coating. The coating is uniform, and the quality fluorocarbon coating has a metallic luster, bright color and obvious three-dimensional effect. The fluorocarbon spray coating with improper spray equipment will cause uneven color, shadow on the surface or weak coating. It greatly affects the decorative effect of fluorocarbon. In order to achieve a good spraying effect, high-voltage electrostatic electric spray guns are used. The United States, Japan, Germany and other countries produce various types of spray guns in various forms. Each has its own characteristics.

The fluorocarbon spraying process mostly uses multi-layer spraying to give full play to the durability and weather resistance of Kynar500 metallic paint. From the front surface treatment of PVDF Aluminum Profile to the spraying process, strict quality control is required, and the final product must be made in the United States. Industry Association AAMA-605.02.90 standard.

| Aluminum Alloy | 6063, 6063A, 6061, 6463, 6463A, 6060, 6005, 6082, etc. |

| Temper | T4, T5, T6 |

| Quality Standard | China National Standard GB/T 5237-2008 (High Precision Class), China National Standard GB/T 6892-2006(High Precision Class) |

| Quality Certificate | ISO 9001:2015, ISO 14001:2015, CQM Certification |

| Application | Aluminum window and door frames, curtain walls, railings, furniture decoration, heat sinks, industrial parts, railway vehicles, etc. |

| Surface Treatment

| Anodizing: Silver, champagne, bronze, black, gold, titanium, imitating steel, etc. |

| Electrophoresis: Sliver, champagne, black, golden, titanium, etc. | |

| Power coating: RAL normal color, or customize customer color samples | |

| Polishing: Mechanical polishing or chemical polishing | |

| Wood Imitation: Normal wooden color or customized wooden color | |

| Fluorocarbon Coating: AkzoNoble color or customize customer color samples | |

| Deep Processing Ability | Drilling, punching, bending, CNC, aluminium profile fabrication, Precise cutting etc. |

| MOQ | 500 kgs to 3,000 kgs |

| Packing Details | Protection film and hot shrink plastic film / EPE foam packing / brown paper packing / wooden packing / Metal pallet or depend on clients special requirement. |

| Payment Term

| 1) T/T: 30% of total value as deposit by T/T within 3 days to confirm the order, and the balance to be paid by T/T before loading the container. |

| 2) L/C: 30% of total value as deposit to be paid by T/T within 3 days to confirm the order, and the balance to be paid by L/C at sight after loading the container. | |

| 3) Big order: Pay 30% of total value as deposit by T/T within 3 day to confirm the order, and the balance to be paid by T/T after delivery against the copy of B/L. |

A: Our factory is located in Foshan City, China, it takes about an hour from Guangzhou Baiyun Airport to our factory, about an hour from Canton Fair.

A: Our minimum order quantity is 500 KGS to 3,000 KGS.

A: For normal size profiles, it takes about 7-10 to fabricate the dies and make the qualified samples.

A: We can complete the orders of mill finish profiles about 10 days, the orders of anodized/powder coated in 15 to 20 days. We can arrange the shipment within 25 days.

A: We have exported our profiles to South East Asia, Middle East, East Europe, South America and Africa, etc.

If you are interesting in our product, please contact us for more details.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.